The global charcoal briquettes market size is RMB 15.041 billion in 2023 and is expected to reach RMB 24.779 billion in 2029, with a CAGR of 8.25% during the forecast period. The production process of charcoal briquettes is relatively simple, with small equipment investment and high production efficiency. A small set of charcoal briquettes production equipment can produce several tons of products per day, with considerable profits.

How to Make Charcoal Briquettes?

To make charcoal briquettes, generally some specific equipment is needed: crusher, dryer, charcoal forming machine and charcoal carbonization furnace, but the process design may be different according to different raw materials, output and customer requirements. We are a professional manufacturer and supplier of charcoal briquette making equipment, you can contact us for more information!

Raw materials for making charcoal briquettes

charcoal briquettes raw materials

- The main raw materials for making charcoal briquettes are coal and charcoal powder; at the same time, some industrial wastes, such as coal slag, sawdust, etc., can be used.

- The raw materials of charcoal are mostly derived from agricultural and forestry wastes, such as discarded fruit tree branches, sawdust, bamboo chips, etc.

- The selection of coal focuses on its calorific value and volatile content, and usually a specific variety of anthracite or bituminous coal is selected.

- Anthracite has less smoke when burning, which can improve the overall environmental protection of briquettes; the appropriate volatile matter of bituminous coal can ensure the ignition performance.

- When making charcoal briquettes, charcoal generally accounts for 30% - 50%, and coal makes up the rest. The specific proportion is adjusted according to the product positioning, aiming to have both high calorific value and easy combustion characteristics.

What kind of machinery is needed to make charcoal briquettes?

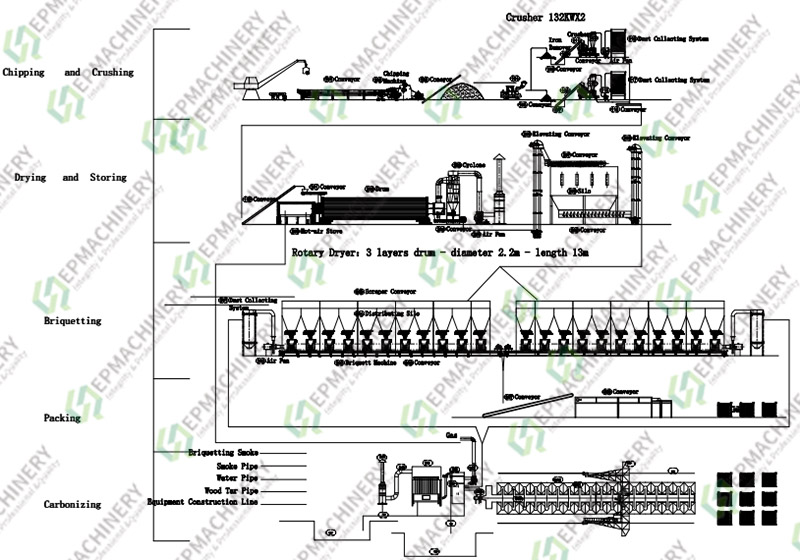

Making charcoal briquettes requires a variety of mechanical equipment. The following shows you how charcoal briquettes are made.

Crushing

Crush machine is essential in most cases

Wood, sawdust and wood chips are cut into small pieces by slicers and then sent to crushers to make particles of about 1-3 mm;

Coal is also processed by crushers and coal mills to a similar particle size.

In charcoal production, if your raw material is powder such as sawdust or coal powder, you can ignore this equipment.

Drying raw material moisture

Dryer is necessary equipment for making charcoal briquettes. To make high-quality charcoal sticks/briquettes, it is crucial to accurately control the moisture content of the raw materials within an appropriate range.

Generally speaking, the ideal moisture content of raw materials for making charcoal sticks is 12%-18%;

The moisture content of raw coal for making briquettes is generally controlled at around 8%-12%.

Charcoal Briquette Binder

When making charcoal briquettes, it is necessary to add a binder.

- It helps to form, by relying on the bonding force to gather charcoal and coal particles into compact briquettes, and improve the forming rate;

- It helps to burn, so that the particles are evenly distributed, the combustion is full and stable, and the combustion speed is regulated;

What are the commonly used binders for making charcoal briquettes?How to choose a suitable binder to make charcoal briquettes?(read more about binders)

Charcoal briquette molding

Charcoal briquetting machine is also called charcoal making machine. Charcoal making machine or charcoal briquetting machine is the key equipment for making charcoal briquettes. Commonly used charcoal briquetting machines are hydraulic or stamping type. Common mold shapes are round and square, with diameters ranging from 5 to 15 cm. The pressure is controlled at 10 to 20 MPa, and the density of the briquette after molding can reach 1.0 to 1.3 g/cm3.

Semi finished charcoal

Charcoal Making Briquette Machine

carbonization

This is the last step of charcoal making.

Charcoal carbonization furnace (suspended carbonization furnace)

Charcoal carbonization furnace is another kind of machinery we must buy to make charcoal briquettes. It is also a charcoal carbonization equipment that is more recognized by more and more charcoal manufacturers.

Industrial scale charcoal underground kiln

For large charcoal briquette factories (production capacity exceeds 10 tons of charcoal briquettes per day), we will provide underground kilns. This underground kiln can be composed of hundreds of single small kilns, all of which are integrated. At the same time, we are also equipped with smoke purification and recovery systems.

Packaging and Storage

Charcoal briquettes are packaged and shipped out after passing the inspection. They are usually packaged in moisture-proof plastic woven bags or paper bags with quantitative packaging.