The development of charcoal briquette production line utilizes wood residues and crop waste to produce efficient and environmentally friendly charcoal briquettes to meet catering, home heating and industrial needs, with considerable profits.

The total cost of a complete biomass charcoal briquette production line is mainly up to raw materials and production capacity. Normally, the total cost will be 20,000-300,000USD roughly. If you are interested in this production line, please tell us your specific raw materials and the production capacity you expect, then we can make proposal for you, and quote shipping cost, installation and commissioning cost, etc.

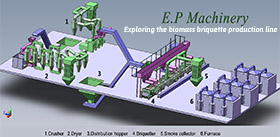

A complete biomass charcoal briquette production line includes Wood Chipping Machine - Belt Conveyor (with Iron Remover) – Hammer Mill – Belt Conveyor (with Iron Remover) – Buffering Hopper – Belt Conveyor – Dryer – Belt Conveyor – Distributing Hopper – Briquette Machine – Belt Conveyor – Carbonization Furnace – Packing Machine.

A complete biomass charcoal briquette production line

Investment cost and benefits of charcoal briquette production line

The costs and benefits of investing in a charcoal briquette production line vary depending on scale, degree of automation and regional differences. The following is a rough analysis:

▌Small production line:

The investment is relatively low, including basic equipment such as crusher, dryer, briquette machine and carbonization furnace, generally around $14,000−$42,000.

Taking a production line that produces 1 ton per day as an example, the profit per ton is US$140-210. Based on 30 days of production per month, the monthly profit is US$2,800-4,200, and the annual profit is approximately US$33,600-50,400. The return on investment can reach 240%-360%, and the payback period may be 3-6 months.

▌Medium-sized production line:

The quality and automation of charcoal briquette equipment are relatively high, and it may also be equipped with auxiliary equipment such as screw feeders and conveyors. The equipment investment is about 42,000−140,000.

Assuming a profit of $112-168 per ton, 5 tons per day, 30 days per month, monthly profit is $11,200-16,800, and annual profit is about $134,400-201,600. The return on investment is about 320%-480%, and the payback period may be 6-12 months.

▌Large production line:

Large charcoal briquette production line with a daily output of more than 30 tons, most of the equipment is customized, with high automation and high production efficiency, and the investment is usually more than $140,000.

If the profit per ton is about $140, 30 tons are produced per day, 30 days per month, the monthly profit is about $84,000, and the annual profit is about $1,008,000. The return on investment can reach 1440%, but due to the long initial construction and market development time, the investment recovery period may take 12-24 months.

Charcoal briquette production line has high return on investment and stable market demand, suitable for small and medium-sized enterprises.

EP Machinery is a professional biomass fuel briquette machinery manufacturer and supplier in China, we have built many successful charcoal briquette projects for customers all over the world, including small briquetting plants and highly automated complete charcoal briquette briquetting production lines.

This is a small briquette production line, including a small hammer mill, airflow dryer, two distribution bins and 2 rod making machines.

How long is the construction period of a biomass charcoal briquette production line?

The construction period of a charcoal briquette production line varies depending on factors such as scale and complexity, and is generally as follows:

| Small charcoal briquettes production line | Medium charcoal briquettes production line | Large charcoal briquettes production line | |

|---|---|---|---|

| Planning and Design: | (Communicate with equipment suppliers and determine the solution) 3-5 days | (Involving more complex process flow and equipment layout) 5-7 days | (It is necessary to consider various factors and conduct detailed feasibility study and design demonstration) 7-10 days |

| Equipment procurement and transportation: | (Purchase conventional equipment) about 7-10 days | (There are many devices and some may be customized) 15-20 days | (Most equipment is customized, and the manufacturing and transportation cycle is long) 30-60 days |

| Factory construction: | 15-30 days | 30-60 days | 60-90 days |

| Equipment installation and debugging: | 5-7 days | 10-15 days | 15-20 days |

| Trial production: | 3-5 days | 7-10 days | 10-15 days |

| Total: | 1-2 months | 2-3 months | 3-6 months |